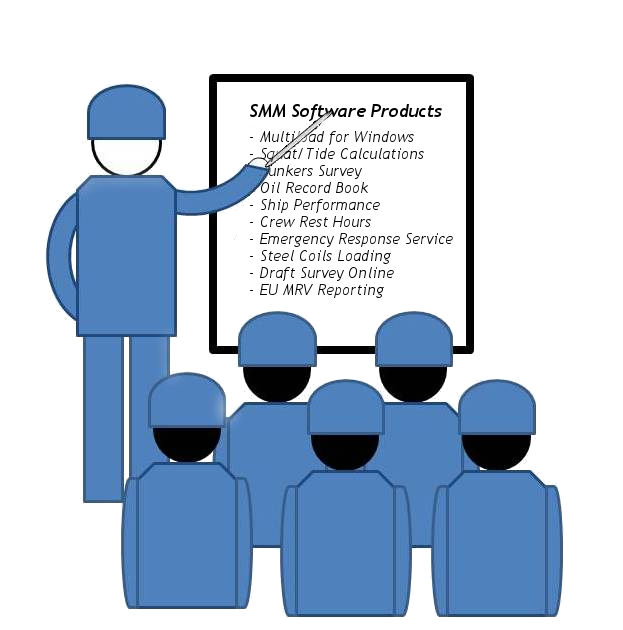

Welcome to SMM Training Center |

|

|

|

|

Which is the best practice for C/Es, changeover is effected?

|

|

|

In merchant shipping, it is important once bunkers samples analysis results are available to prompt C/Es to alter the Low Calorific Value (LCV) on M/Es settings assuring better combustion efficiency, in case of fuel changeover. |

|

|

How can I have an accurate performance prediction model which provides guidance about speed / consumption correlation subject to a certain draft condition?

|

|

|

AA) Slip Method - Reference Values for M.E. / Fuel Performance |

|

|

What Owners should consider?

|

|

|

• International Towing Tank Committee (ITTC) Recommendations shall be followed in model tests by Tank facilities. • Model test reports must include Performance Data Set (Speed, Power RPM) at different drafts, at different speeds (slow steaming, normal operation etc) and at the trial condition and service condition. (Initial reference conditions). • Model test reports shall include all measurements and calculations. • Numerical Analysis for Added Resistance (Wind and Waves) should be requested and the results to be for Speed-Power-RPM, at different drafts at different speeds (slow steaming, normal operation etc.) and at different weather conditions. • In case of any Energy Saving Devices such as Duct, model tests should be carried with and without ESD (prior and upon such installation). • All information to be in tabular form. • Drafts for model tests shall include at least Scantling, Ballast and Design drafts. • Model Tests ought to be carried out in the presence of Owners. • Video recording and Photographs of the model tests shall be agreed to be provided by facility. • The correlation coefficients shall be fixed and disclosed prior the model tests. • The model tank facility to be certified as per ISO 17025. • The Light Running Margin (LRM) from model test to be above the minimum LRM as agreed in Technical specification, whilst the former to be confirmed during sea trials. • Propeller Cavitation tests shall be carried out with similarity at location where Cavitation is observed during the tests. |

|

All Rights Reserved 1986 - © www.smmnet.com